UHT starts CLU converter for FeMn at HIRA, India

In December, 2016 UHT commissioned a CLU® converter with the capacity of 12 tonnes at Hira Power & Steel in Raipur, Chhattisgarh, India. The CLU converter will be used for refining HC FeMn to MC and LC FeMn to meet the increasing market demand for a superior product.

UHT’s scope of supply includes a complete converter package comprising vessels, trunnion ring, hydraulic converter drive (HCD), gas mixing station, Level 1 PLC and Level 2 real-time UTCAS® Process Control System as well as process design and engineering of auxiliaries.

The CLU process is cost-effective and ideal for MC and LC FeMn production due to the excellent temperature control without alloy dilution. Super-heated steam which is utilized as one of the process gases acts as coolant by controlling the temperature in the metal bath through the endothermic reaction that occurs when the steam is split into Oxygen and Hydrogen after injection. Thus, by balancing the temperature, the need for cooling material decreases and the Mn yield is enhanced.

UHT – Uvån Hagfors Teknologi AB is a Swedish engineering company and well established global supplier of metallurgical processes and Technologies to the iron, steel, stainless steel and ferroalloy industry. We concentrate our activities to AOD and CLU® converter refining and GRANSHOT® metal granulation.

UHT starts CLU converter for FeMn at HIRA, India

In December, 2016 UHT commissioned a CLU® converter with the capacity of 12 tonnes at Hira Power & Steel in Raipur, Chhattisgarh, India. The CLU converter will be used for refining HC FeMn to MC and LC FeMn to meet the increasing market demand for a superior product.

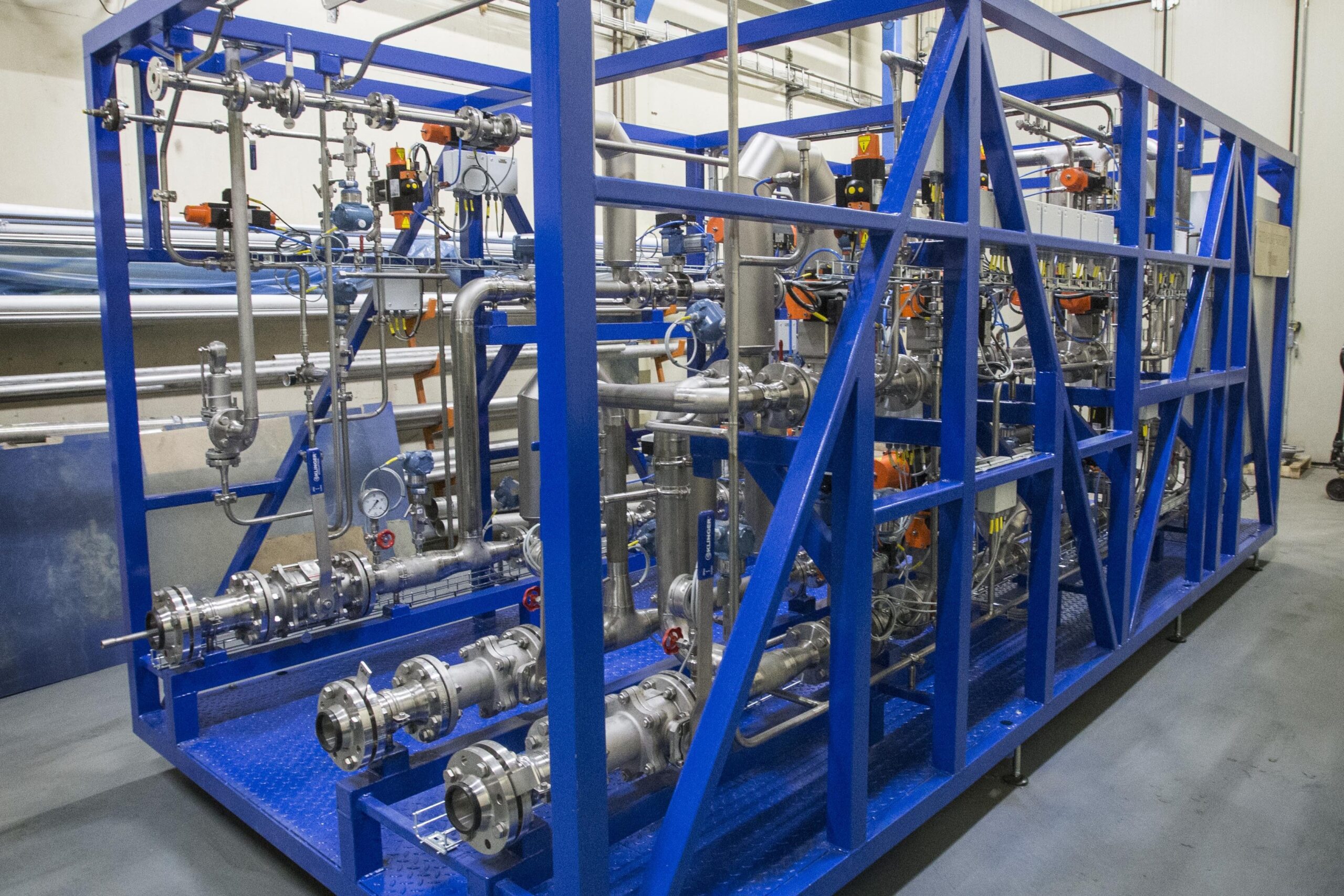

UHT’s scope of supply includes a complete converter package comprising vessels, trunnion ring, hydraulic converter drive (HCD), gas mixing station, Level 1 PLC and Level 2 real-time UTCAS® Process Control System as well as process design and engineering of auxiliaries.

The CLU process is cost-effective and ideal for MC and LC FeMn production due to the excellent temperature control without alloy dilution. Super-heated steam which is utilized as one of the process gases acts as coolant by controlling the temperature in the metal bath through the endothermic reaction that occurs when the steam is split into Oxygen and Hydrogen after injection. Thus, by balancing the temperature, the need for cooling material decreases and the Mn yield is enhanced.

UHT – Uvån Hagfors Teknologi AB is a Swedish engineering company and well established global supplier of metallurgical processes and Technologies to the iron, steel, stainless steel and ferroalloy industry. We concentrate our activities to AOD and CLU® converter refining and GRANSHOT® metal granulation.

News & stories

Hydraulic converter drive

Unique AOD converter tilting solution Load imbalance and gas injection cause severe converter vibrations during AOD refining which leads to extensive wear on equipment such as the converter drive. [...]

UHT Hackathon 2024

Utveckla ett spel och lär dig mer om programmering! När: 9 mars, kl 9-20 Var: Görsjövägen 3, Hagfors För vem: Gymnasieelever - inga krav på förkunskaper Anmälan: senast 1 mars genom formuläret nedan Obs! [...]

Gas mixing station for AOD converters

Accurate gas distribution UHT's gas mixing station is a versatile solution for distribution of oxygen, argon, nitrogen, and compressed air to the AOD converter. The gas mixing station is engineered, [...]

Talk to an expert

Our mission is to support advanced metal producers to refine their metal processing, increase value, and stay competitive.

Our heritage makes us understand requirements on operations to perform. We focus on stability, throughput and safety, while preparing for the future demands driven by the global transitions.

Fill in the form and book a meeting with one of our experts to discuss your current situation, business objecives and options to obtain a more effeicient metals production.