UTCAS® boosts productivity at OUTOKUMPU Avesta

OUTOKUMPU Avesta’s Investments and Project Director Ola Modigs concludes:

– The UTCAS system is an important way for OUTOKUMPU to further trim the operational and economic performance in our steel making processes, which is highly necessary to meet the demand for high quality stainless steel grades combined with an increasing need for operational flexibility while continuously improving our cost efficiency. The UTCAS platform also allows us to integrate and create direct and rapid process data communication between the different operations themselves and that our process and operator staff will engage with the processes through a common interface, again this will create additional results in our operations.

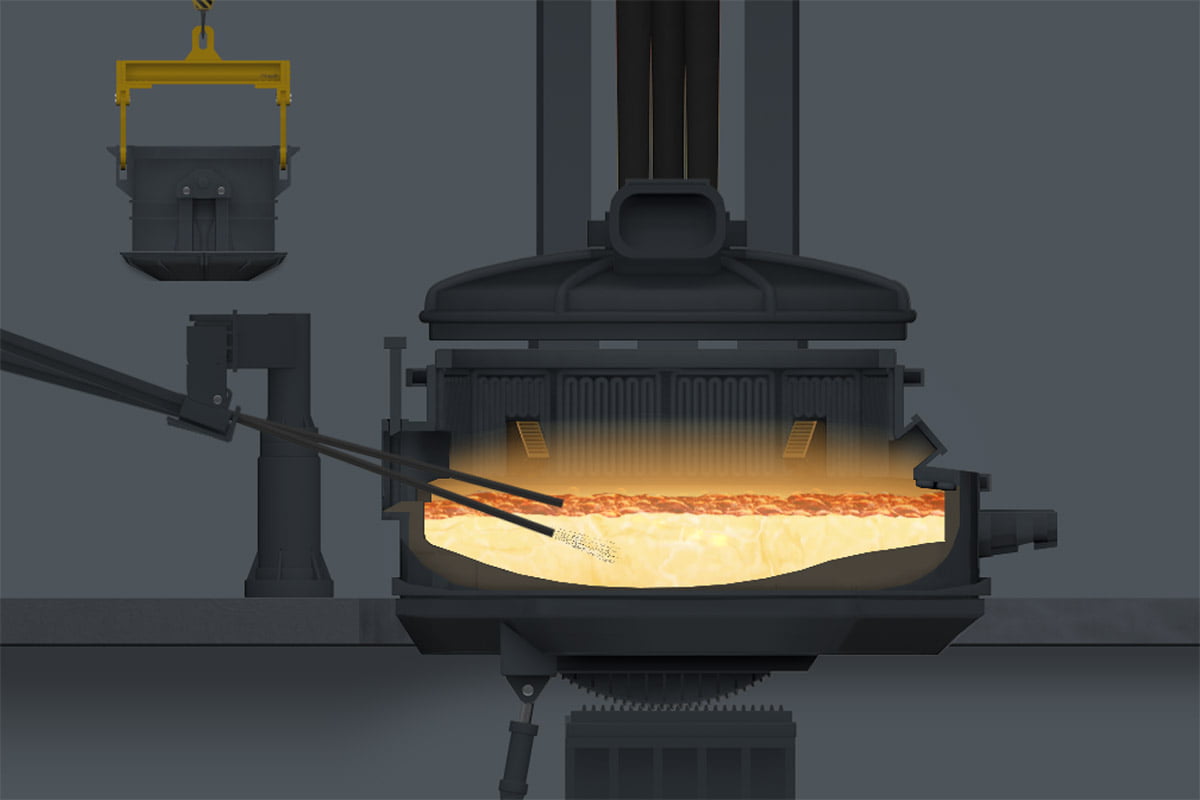

UHT is a Swedish engineering company with roots in the stainless and special steel production delivering complete AOD & CLU® converter refining solutions includes the simulation and real-time UTCAS® process control system platform, which today is available for EAF, AOD, VOD/VD and LF. Currently there are 20 UTCAS® deliveries worldwide from UHT.

OUTOKUMPU Stainless is a global leader in stainless steel and high performance alloys. The production in Avesta, Sweden, is today one of the world‘s most productive and they specialize in the production of stainless steel grades with a high level chromium content.

UTCAS® boosts productivity at OUTOKUMPU Avesta

OUTOKUMPU Avesta’s Investments and Project Director Ola Modigs concludes:

– The UTCAS system is an important way for OUTOKUMPU to further trim the operational and economic performance in our steel making processes, which is highly necessary to meet the demand for high quality stainless steel grades combined with an increasing need for operational flexibility while continuously improving our cost efficiency. The UTCAS platform also allows us to integrate and create direct and rapid process data communication between the different operations themselves and that our process and operator staff will engage with the processes through a common interface, again this will create additional results in our operations.

UHT is a Swedish engineering company with roots in the stainless and special steel production delivering complete AOD & CLU® converter refining solutions includes the simulation and real-time UTCAS® process control system platform, which today is available for EAF, AOD, VOD/VD and LF. Currently there are 20 UTCAS® deliveries worldwide from UHT.

OUTOKUMPU Stainless is a global leader in stainless steel and high performance alloys. The production in Avesta, Sweden, is today one of the world‘s most productive and they specialize in the production of stainless steel grades with a high level chromium content.

News & stories

Hydraulic converter drive

Unique AOD converter tilting solution Load imbalance and gas injection cause severe converter vibrations during AOD refining which leads to extensive wear on equipment such as the converter drive. [...]

UHT Hackathon 2024

Utveckla ett spel och lär dig mer om programmering! När: 9 mars, kl 9-20 Var: Görsjövägen 3, Hagfors För vem: Gymnasieelever - inga krav på förkunskaper Anmälan: senast 1 mars genom formuläret nedan Obs! [...]

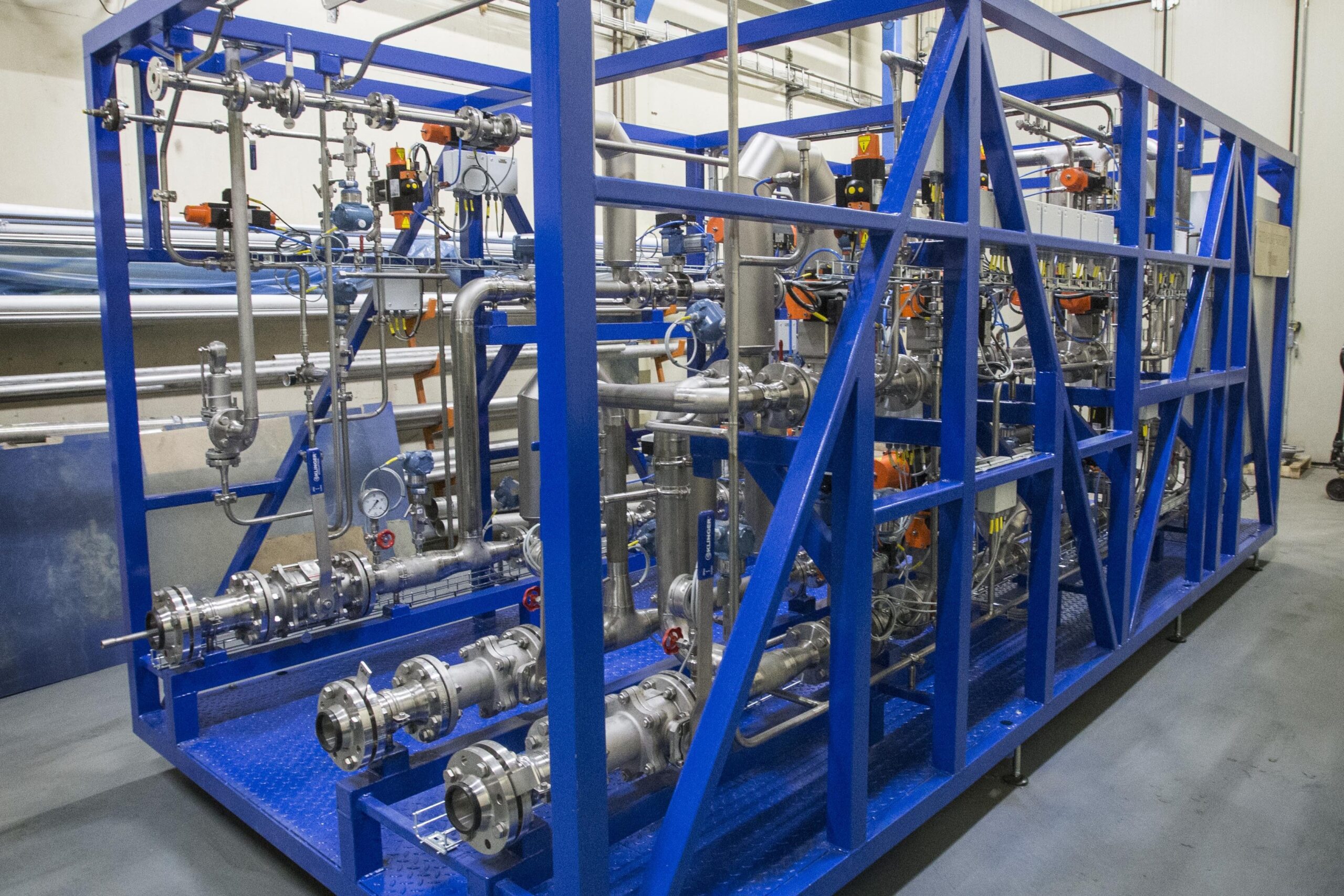

Gas mixing station for AOD converters

Accurate gas distribution UHT's gas mixing station is a versatile solution for distribution of oxygen, argon, nitrogen, and compressed air to the AOD converter. The gas mixing station is engineered, [...]

Talk to an expert

Our mission is to support advanced metal producers to refine their metal processing, increase value, and stay competitive.

Our heritage makes us understand requirements on operations to perform. We focus on stability, throughput and safety, while preparing for the future demands driven by the global transitions.

Fill in the form and book a meeting with one of our experts to discuss your current situation, business objecives and options to obtain a more effeicient metals production.