Process control

UTCAS®

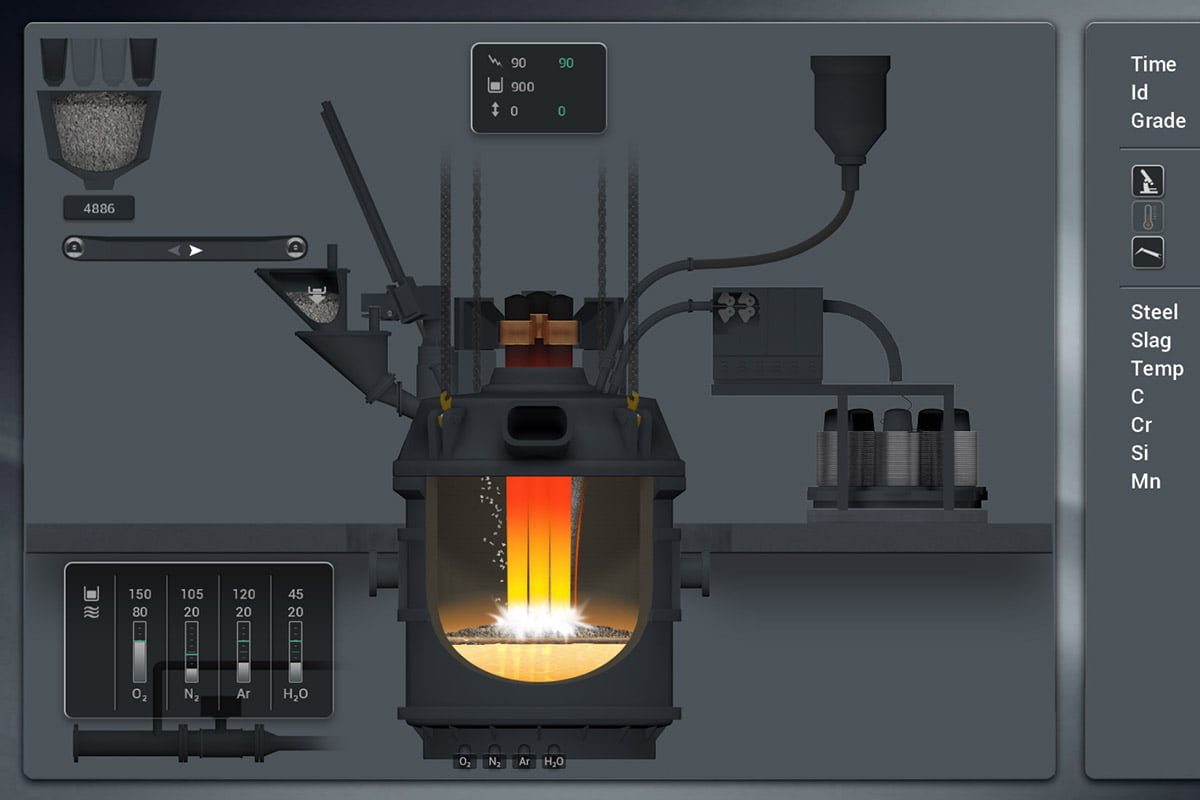

The UTCAS steel production management system ensures operational excellence in advanced metals processing, enabled by data-driven process design, standardisation, and optimisation models.

UTCAS has a proven track record of reduced consumbables consumption, decreased processing time, decreased refractory wear, and improved processing flexibility and target precision.

Full steel shop control by UTCAS® real-time system

What makes UTCAS® a unique solution?

UTCAS® for metals producers

UTCAS® is a powerful real-time dynamic process control system for metal production. Based on the actual in-coming data and present process conditions, UTCAS optimizes the processing to obtain maximum operational performance, regardless of starting conditions.

UTCAS assists the operator finding the most effictive path towards the end targets keeping metal composition, temperature, mass, and time within specifications. The system offers an exstensive tool package for process design, production evaluation, and continuous improvement driven by process data.

UTCAS supports world-class processing at premium steel producers such as BGH, SANDVIK Kanthal, OUTOKUMPU Avesta, and UDDEHOLM. UTCAS is available as a stand-alone steel production management system or as part of all of UHT’s AOD & CLU deliveries.

Steel

UTCAS for steelmakers offer improved production stability and reduced interference down-stream causing costly interruptions. UTCAS covers process and production control for the most common operations such as EAF, AOD/CLU), VD/VOD, LF, and ladle treatments. The flexibility in set-up allows UTCAS to be configured for any plant configuration. Each heat is given a tailored process plan based on starting conditions, process design strategy, and final end targets. UTCAS then finds the optimal solution based on selected priority such as minimum cost or processing time.

Ferroalloys

Ferroalloys post-taphole refining adds considerable value to the metal product, typically by reducing the carbon content. UTCAS calulates the process plan and treatment steps to reach a given product specification with a minimum of metal loss and operational costs. A combination of the UTCAS process control and a CLU converter process is probably the most common global set-up for advanced refining operations in ferroalloys production, sometimes in combination with ladle treatments.

Foundries and special steels

The processing of special steel and foundry operations includes advanced alloys with strict composition requirements. UTCAS minimizes costs of raw material additions by calculating the most cost-effective material mix including expected refining reactions that remove detrimental elements.

UTCAS covers the most common processes in foundry and special steel processing such as EAF, induction furnace, AOD/CLU, and ladle treatments.

Increase the effectivness of the industry

Talk to an expert

Our mission is to support advanced metal producers to refine their metal processing, increase value, and stay competitive.

Our heritage makes us understand requirements on operations to perform. We focus on stability, throughput and safety, while preparing for the future demands driven by the global transitions.

Fill in the form and book a meeting with one of our experts to discuss your current situation, business objecives and options to obtain a more effeicient metals production.